São Tomé e Príncipe desponta como um dos destinos mais autênticos e subexplorados da África Ocidental, oferecendo aos viajantes uma experiência genuína longe do turismo de massa. Este arquipélago de duas ilhas no Golfo da Guiné combina praias virgens, florestas tropicais exuberantes, patrimônio colonial único e biodiversidade endêmica que transformam cada visita numa descoberta memorável.

Contexto Geográfico e Histórico Singular

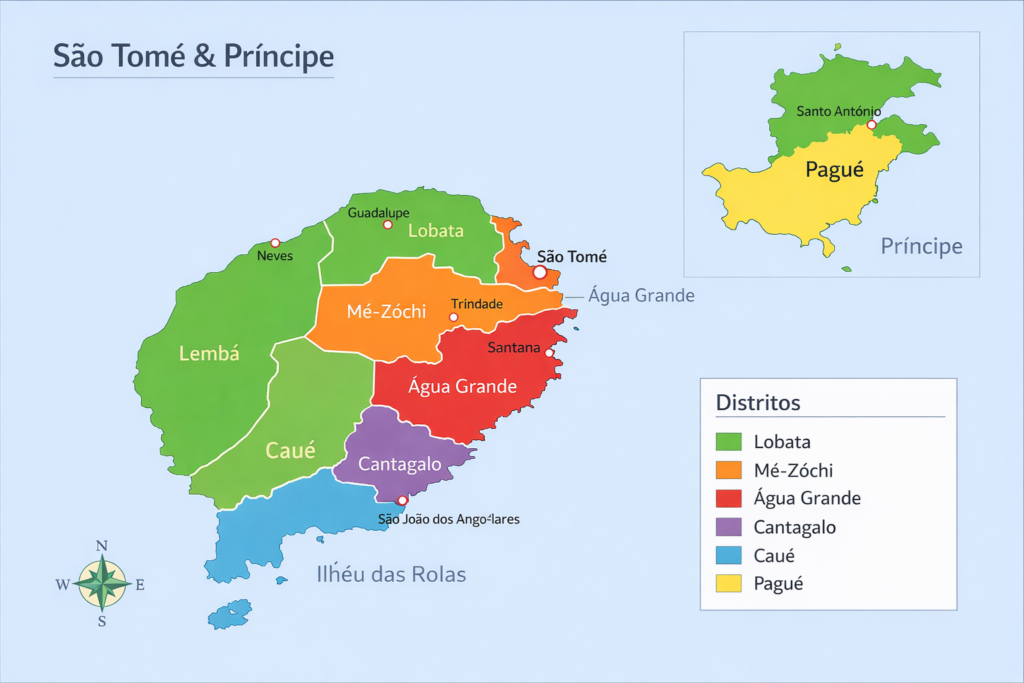

Localizado a aproximadamente 250 quilômetros da costa do Gabão, o arquipélago é composto por duas ilhas principais: São Tomé (859 km²) e Príncipe (142 km²), além de ilhotas adjacentes como Rolas e Caroço. A descoberta portuguesa no século XV transformou estas terras inabitadas num importante entreposto do comércio atlântico e, posteriormente, no maior produtor mundial de cacau entre 1908 e 1920.

Marco Histórico Relevante para o Turismo Atual:

- As roças (antigas plantações coloniais) hoje funcionam como alojamentos históricos únicos, como a Roça São João e a Roça Sundy

- O Marco Zero no Ilhéu das Rolas divide o planeta entre hemisférios norte e sul – experiência geográfica rara para turistas

- A independência em 1975 preservou uma cultura crioula singular, resultado da fusão entre portugueses, africanos e descendentes de escravizados

Clima e Períodos Ideais para Visita

O clima equatorial úmido define a experiência turística no país, com variações sazonais que impactam diretamente nas atividades recomendadas.

| Época do Ano | Meses | Precipitação Média | Temperatura Média | Atividades Prioritárias |

|---|---|---|---|---|

| Época Seca Principal | Junho a Setembro | 50-100 mm/mês | 24-28°C | Mergulho, trilhas na floresta, observação de aves |

| Curta Estação Chuvosa | Outubro a Novembro | 150-200 mm/mês | 26-30°C | Visitas culturais, degustação de cacau, passeios de barco |

| Grande Estação Chuvosa | Dezembro a Maio | 250-400 mm/mês | 27-31°C | Experiências gastronômicas, SPA em roças históricas, fotografia de paisagens verdes |

Dica Específica: Julho e agosto são ideais para avistamento de baleias jubarte na costa sul de São Tomé, enquanto abril-maio oferecem as melhores condições para observar tartarugas marinhas desovando nas praias de Jalé e Praia Inhame.

Roteiros Especializados por Perfil de Viajante

Para Amantes da Biodiversidade Endêmica

São Tomé e Príncipe abrigam 28 espécies de aves endêmicas, incluindo o raro papagaio-de-São-Tomé (Psittacus erithacus princeps) e o tecelão-de-São-Tomé. A Reserva Natural Ôbo cobre 30% do território nacional e oferece trilhas específicas:

| Trilha | Duração | Dificuldade | Espécies Endêmicas Avistáveis |

|---|---|---|---|

| Pico Cão Grande | 4-5 horas | Elevada | Andorinha-do-rio-de-São-Tomé, pomba-imperial |

| Lagoa Amélia | 3 horas | Moderada | Sunbird-de-Príncipe, tecelão-de-Príncipe |

| Cascata São Nicolau | 2 horas | Leve | Papagaio-de-São-Tomé, tartaruga-gigante (reintroduzida) |

Para Entusiastas do Cacau de Origem

O país produz cacau single-origin premiado internacionalmente. Visitantes podem participar de experiências imersivas:

- Roça Diogo Vaz: A mais antiga plantação em operação (desde 1822), com tour de colheita e processo artesanal de fermentação

- Clube do Cacau em Santo António: Degustação comparativa de chocolates de diferentes terroirs das ilhas

- Fazenda Monte Café: Demonstração do processo completo desde a vagem até a barra de chocolate 70% cacau

Para Aventureiros Aquáticos

As águas cristalinas abrigam recifes de coral pouco explorados e naufrágios históricos:

- Baía das Agulhas: Mergulho com cardumes de barracudas e recifes de coral negro

- Ilhéu das Rolas: Drift dive com correntezas suaves e visibilidade superior a 30 metros

- Praia Jale: Surf de ondas longas ideais para intermediários (maio a outubro)

Gastronomia como Experiência Cultural

A culinária santomense reflete sua história multicultural com ingredientes locais transformados em pratos únicos:

Pratos Essenciais a Experimentar:

- Calulu: Peixe seco ou frango cozido com quiabo, dendém e legumes – considerado prato nacional

- Pão de coco com peixe grelhado: Especialidade da ilha do Príncipe, servido nas praias de Banana e Boi

- Cachupa rica: Versão local do prato cabo-verdiano, com caranguejo e marisco fresco

- Água de coco direto do fruto: Servida em quiosques das praias de Ponta Figo e Praia Inhame

Mercados Locais para Experiência Autêntica:

- Mercado Municipal de São Tomé (cidade): Funciona das 6h às 13h, com peixe fresco descarregado diretamente dos barcos

- Mercado de Santo António (Príncipe): Pequeno mas autêntico, especializado em frutas tropicais raras como abiu e jaca-d’anta

Logística Prática para o Viajante

Transporte entre Ilhas:

- Voos STP Airways: 20 minutos, 3 voos diários (aprox. 120€ ida)

- Ferry boat M/V Príncipe: 2h30, operação irregular sujeita a condições marítimas (25€)

Alojamento por Categoria:

- Luxo Sustentável: Sundy Praia (Príncipe) – único resort com certificação Biosphere Responsible Tourism

- Experiência Histórica: Roça São João (São Tomé) – alojamento em antiga residência colonial com 150 anos

- Imersão Local: Pensão Dona Maria (Santo António) – gestão familiar com refeições caseiras

Documentação Necessária:

- Visto obrigatório para brasileiros e portugueses (emitido gratuitamente no aeroporto ou consulado)

- Vacinação contra febre amarela exigida (com certificado internacional)

- Recomenda-se profilaxia contra malária mesmo para estadias curtas

Preservação e Turismo Responsável

O turismo em São Tomé e Príncipe enfrenta desafios de sustentabilidade devido à fragilidade dos ecossistemas insulares. Viajantes conscientes devem:

- Utilizar protetor solar biodegradável nas praias de desova de tartarugas

- Contratar guias locais credenciados para trilhas na Reserva Ôbo (custo: 25-40€/grupo)

- Evitar coleta de conchas ou corais como lembranças

- Priorizar alojamentos com certificação ambiental ou projetos de conservação comunitária

Descubra a autenticidade do Atlântico profundo com a Voltours Lda.

Planeamos itinerários personalizados em São Tomé e Príncipe com acesso exclusivo a roças históricas, guias especializados em biodiversidade endêmica e experiências gastronómicas com produtores locais de cacau. Solicite hoje mesmo o seu roteiro sob medida para explorar este paraíso insular com profundidade e respeito pela sua cultura única.